Plastic Flat Mesh: A Comprehensive Guide

Plastic flat mesh is a versatile product that has become increasingly popular in various applications over the years. From construction to gardening, packaging to filtration, this type of mesh can be found in a wide range of industries. In this article, we'll dive into what plastic flat mesh is, its types, uses, benefits, and drawbacks.

What is Plastic Flat Mesh?

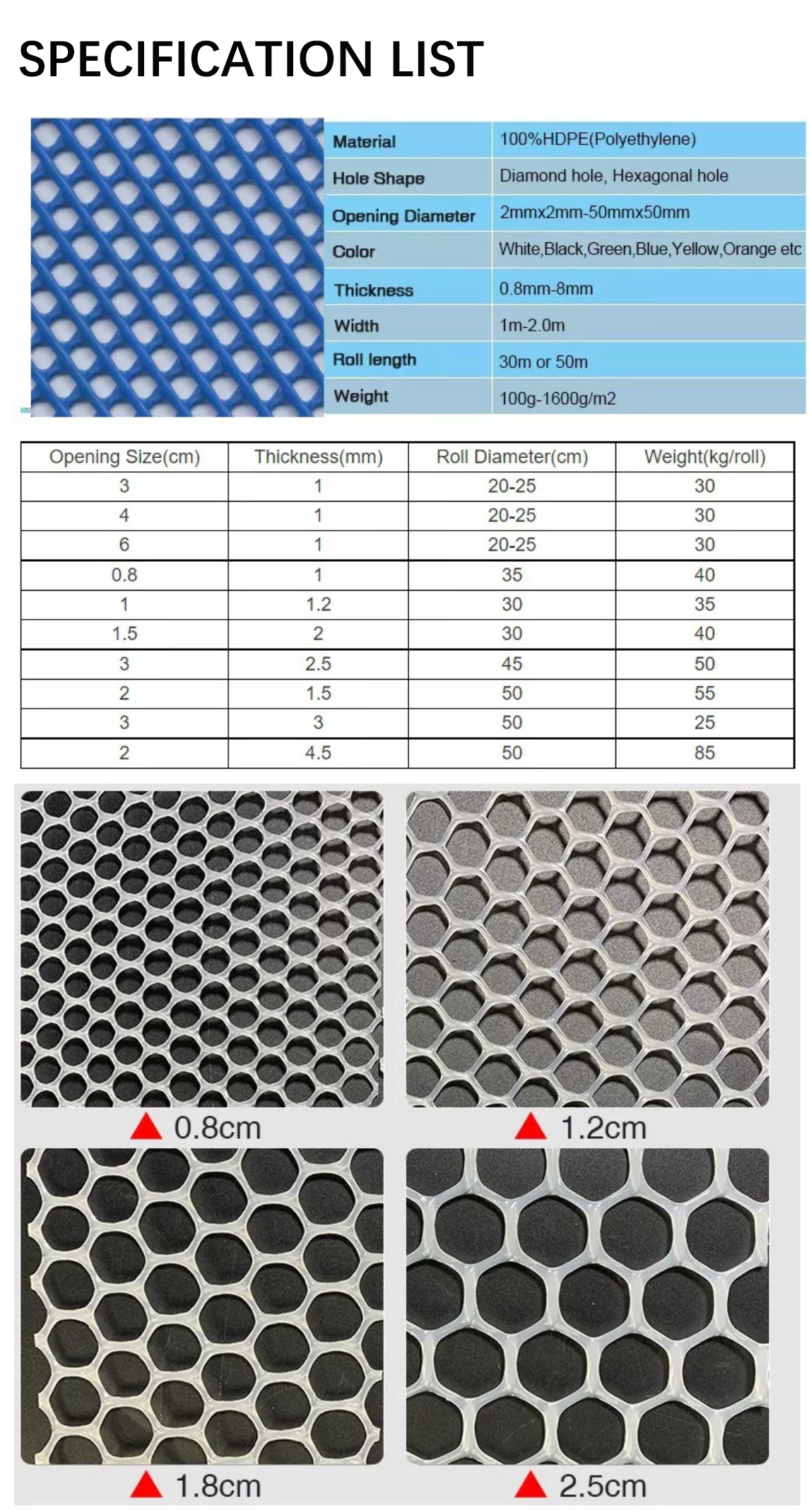

Plastic flat mesh is a type of plastic netting that is flat and flexible. It is made of polyethylene or polypropylene, which makes it lightweight, durable, and resistant to corrosion and chemical damage. The mesh is available in different sizes and colors, depending on the application.

Types of Plastic Flat Mesh

Extruded Plastic Flat Mesh

Extruded plastic flat mesh is made by melting plastic pellets and extruding them into a flat sheet. The mesh has a uniform thickness and is ideal for applications that require a consistent opening size.

Oriented Plastic Flat Mesh

Oriented plastic flat mesh is made by stretching the extruded sheet in two directions. This process results in a mesh that is stronger and more rigid than extruded mesh. It is often used in applications that require higher strength and stability.

Applications of Plastic Flat Mesh

Construction

Plastic flat mesh is commonly used in the construction industry as a reinforcement material for concrete structures. It provides an easy-to-install, cost-effective solution for reinforcing walls, floors, and foundations. It is also used as a safety barrier on construction sites.

Gardening and Agriculture

Plastic flat mesh is used in gardening and agriculture for various purposes, such as plant support, tree protection, and pest control. It is also used as a trellis for climbing plants.

Packaging

Plastic flat mesh is often used in packaging applications to protect fragile items, such as bottles and jars. It is also used as a separator for food items and as a wrapping material for gift baskets.

Filtration

Plastic flat mesh is used in filtration applications to separate solids from liquids. It is commonly used in water treatment plants, aquariums, and fish farms.

Safety and Protection

Plastic flat mesh is used in various safety and protection applications, such as fencing for animals, playgrounds, and sports fields. It is also used as a barrier for debris on highways and in industrial settings.

Benefits of Plastic Flat Mesh

Lightweight

Plastic flat mesh is lightweight, which makes it easy to handle and install. It also reduces transportation costs and requires less support than heavier materials.

Durable

Plastic flat mesh is resistant to corrosion, chemical damage, and impact. It can withstand harsh weather conditions and is less likely to break or crack than other materials.

Cost-effective

Plastic flat mesh is a cost-effective solution for many applications. It is cheaper than metal or fiberglass mesh and requires less maintenance over time.

Easy to Install and Maintain

Plastic flat mesh is easy to install and requires minimal maintenance. It can be cut to size and installed with simple tools, such as scissors and staples.

Drawbacks of Plastic Flat Mesh

Limited Temperature Range

Plastic flat mesh has a limited temperature range and may not be suitable for applications that require high-temperature resistance. It can melt or deform when exposed to high temperatures, which may compromise its integrity.

Vulnerable to UV Damage

Plastic flat mesh is vulnerable to UV damage, which can cause it to become brittle and break down over time. This can reduce its lifespan and effectiveness in certain applications, particularly those exposed to direct sunlight.

Limited Strength and Rigidity

While plastic flat mesh is durable, it has a limited strength and rigidity compared to other materials such as metal or fiberglass. This may limit its application in situations where high strength and rigidity are required.

Conclusion

Plastic flat mesh is a versatile product that can be used in various applications due to its lightweight, durability, and cost-effectiveness. Its drawbacks include limited temperature range, vulnerability to UV damage, and limited strength and rigidity. Despite these limitations, plastic flat mesh remains a popular choice for many industries.

FAQs

What is plastic flat mesh used for in construction?

Plastic flat mesh is commonly used as a reinforcement material for concrete structures and as a safety barrier on construction sites.

Is plastic flat mesh recyclable?

Yes, plastic flat mesh made of polyethylene or polypropylene is recyclable.

How is extruded plastic flat mesh made?

Extruded plastic flat mesh is made by melting plastic pellets and extruding them into a flat sheet.

Can plastic flat mesh be used for filtration?

Yes, plastic flat mesh can be used in filtration applications to separate solids from liquids.

Is plastic flat mesh suitable for high-temperature applications?

No, plastic flat mesh has a limited temperature range and may not be suitable for high-temperature applications.