Galvanized Binding Wire: Properties, Uses, and Benefits

Galvanized Binding Wire: Properties, Uses, and Benefits

Galvanized binding wire is a type of wire that is coated with a layer of zinc to increase its durability and resistance to corrosion. It is widely used in the construction industry for binding materials together and providing support. In this article, we will explore the properties, uses, and benefits of galvanized binding wire.

Table of Contents

- Introduction

- What is Galvanized Binding Wire?

- Properties of Galvanized Binding Wire

- Uses of Galvanized Binding Wire

- Benefits of Galvanized Binding Wire

- How to Choose the Right Galvanized Binding Wire?

- How to Use Galvanized Binding Wire?

- Safety Precautions While Using Galvanized Binding Wire

- Conclusion

- FAQs

1. Introduction

Galvanized binding wire is a versatile and reliable construction material that is used for binding and supporting materials. It is made of high-quality steel wire that is coated with a layer of zinc to prevent corrosion and increase its lifespan. Galvanized binding wire is commonly used in construction, agriculture, and manufacturing industries due to its strength and durability.

2. What is Galvanized Binding Wire?

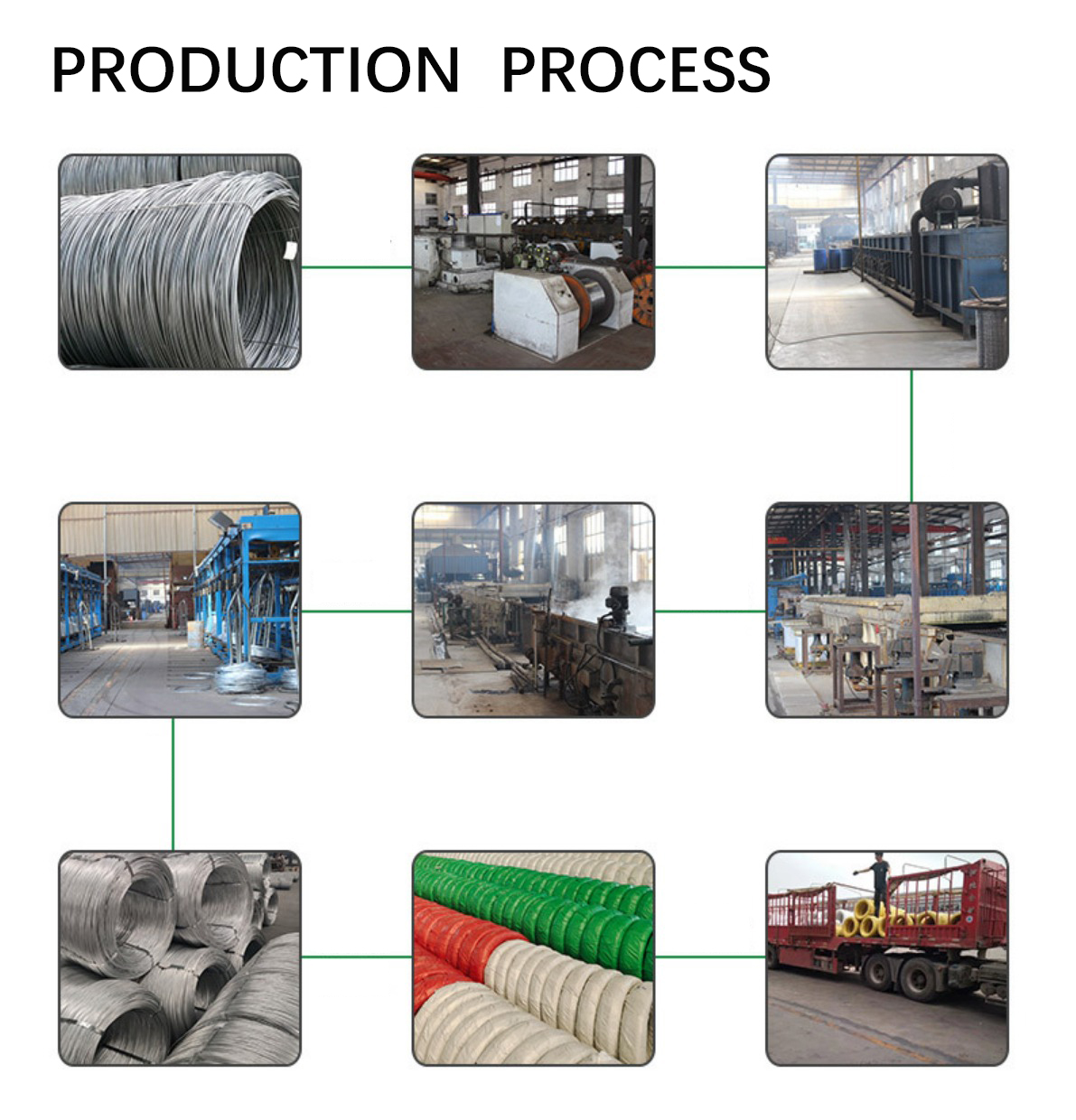

Galvanized binding wire is a type of steel wire that is coated with a layer of zinc through a process called galvanization. This process involves dipping the steel wire into a hot molten zinc bath, which results in the formation of a protective layer of zinc around the wire. The zinc coating provides a barrier between the steel wire and the environment, preventing rust and corrosion.

3. Properties of Galvanized Binding Wire

Galvanized binding wire has several properties that make it an ideal material for construction and other applications. These properties include:

3.1 Durability

Galvanized binding wire is highly durable and resistant to corrosion, making it suitable for use in harsh environments.

3.2 Strength

Galvanized binding wire is made of high-quality steel wire, which gives it excellent strength and allows it to support heavy loads.

3.3 Flexibility

Galvanized binding wire is flexible and easy to bend, making it easy to use for binding and supporting materials.

3.4 Longevity

The zinc coating on galvanized binding wire provides long-lasting protection against rust and corrosion, making it a reliable material for construction.

4. Uses of Galvanized Binding Wire

Galvanized binding wire has many uses in the construction, agriculture, and manufacturing industries. Some common uses include:

4.1 Binding Materials Together

Galvanized binding wire is commonly used to bind materials together, such as reinforcing steel bars in concrete structures.

4.2 Supporting Structures

Galvanized binding wire is used to provide support for structures, such as trellises for plants or fencing for livestock.

4.3 Manufacturing and Packaging

Galvanized binding wire is used in manufacturing and packaging applications, such as bundling products or securing boxes.

5. Benefits of Galvanized Binding Wire

Galvanized binding wire offers several benefits that make it a popular choice for construction and other applications. These benefits include:

5.1 Corrosion Resistance

The zinc coating on galvanized binding wire provides excellent corrosion resistance, making it suitable for use in harsh environments.

5.2 Strength and Durability

Galvanized binding wire is made of high-quality steel wire, which gives it excellent strength and durability.

5.3 Easy to Use

Galvanized binding wire is flexible and easy to bend, making it easy to use for binding and supporting materials.

5.4 Longevity

The zinc coating on galvanized binding wire provides long-lasting protection against rust and corrosion, making it a reliable material for construction.

6. How to Choose the Right Galvanized Binding Wire?

Choosing the right galvanized binding wire depends on several factors, such as the application, the load it will be supporting, and the environment in which it will be used. When selecting galvanized binding wire, consider the following:

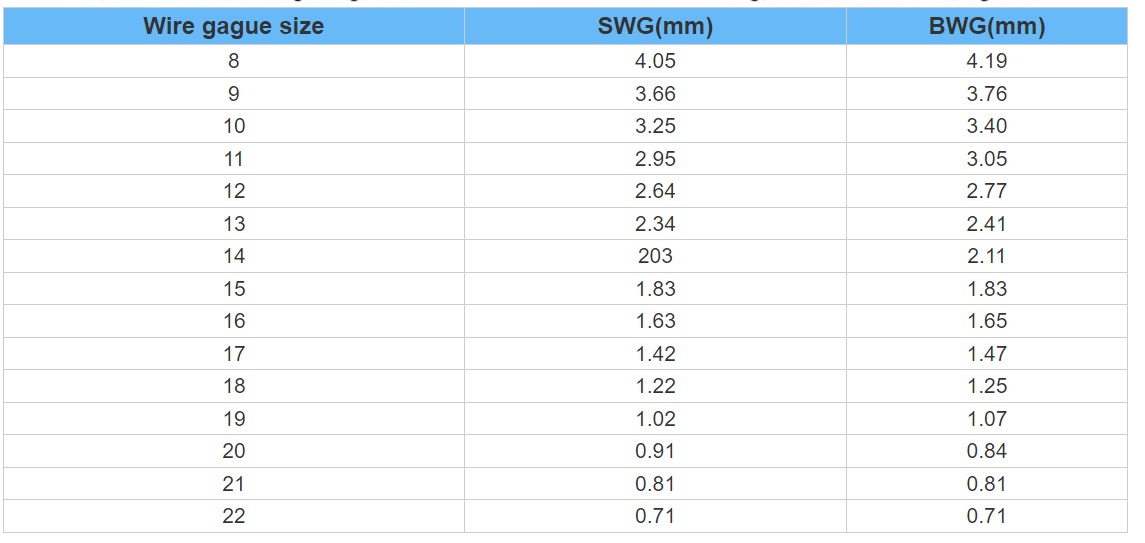

6.1 Wire Gauge

The wire gauge is an important factor to consider when selecting galvanized binding wire. The wire gauge determines the thickness of the wire, which affects its strength and durability. A thicker wire gauge will provide more strength and support, but it may be less flexible and more difficult to work with.

6.2 Coating Thickness

The thickness of the zinc coating also plays a crucial role in determining the durability and corrosion resistance of the wire. Thicker coatings provide better protection against corrosion, but they may also make the wire less flexible.

6.3 Application

Consider the specific application for which you will be using the galvanized binding wire. Different applications require different levels of strength, flexibility, and corrosion resistance. For example, binding wire used in the construction of buildings may require greater strength and durability than wire used in packaging.

7. How to Use Galvanized Binding Wire?

Galvanized binding wire is easy to use and can be bent and cut to fit the specific needs of your project. When using galvanized binding wire, follow these safety tips:

7.1 Wear Protective Gear

Wear protective gloves and safety glasses to protect your hands and eyes from the wire.

7.2 Use Proper Tools

Use wire cutters and pliers to cut and bend the wire. Do not use your hands to bend the wire as this can cause injury.

7.3 Secure the Wire Properly

Make sure the wire is tightly secured to the materials it is binding or supporting. Loose wire can lead to instability and failure.

7.4 Cut the Wire Properly

When cutting the wire, make sure to use sharp wire cutters to prevent frayed ends.

8. Safety Precautions While Using Galvanized Binding Wire

While galvanized binding wire is a safe and reliable material, it is important to follow safety precautions when using it. Some safety precautions to keep in mind include:

8.1 Wear Protective Gear

Always wear protective gloves and safety glasses to protect your hands and eyes from the wire.

8.2 Use Proper Tools

Use wire cutters and pliers to cut and bend the wire. Do not use your hands to bend the wire as this can cause injury.

8.3 Store the Wire Properly

Store the wire in a dry, protected area to prevent it from corroding or becoming damaged.

8.4 Use the Right Wire for the Job

Make sure you are using the correct wire gauge and coating thickness for the job at hand.

9. Conclusion

Galvanized binding wire is a durable and versatile material that is used in a wide range of applications, from construction to manufacturing. Its strength, flexibility, and corrosion resistance make it an ideal choice for binding and supporting materials. When using galvanized binding wire, it is important to follow safety precautions and choose the right wire for the job to ensure the best results.

10. FAQs

-

What is galvanized binding wire used for?

-

Galvanized binding wire is used for binding and supporting materials in the construction, agriculture, and manufacturing industries.

-

What is the difference between galvanized and non-galvanized binding wire?

-

Galvanized binding wire is coated with a layer of zinc to increase its durability and resistance to corrosion, while non-galvanized wire does not have this protective coating.

-

How is galvanized binding wire made?

-

Galvanized binding wire is made by dipping