Galvanized Binding Wire: An Essential Material for Construction and Manufacturing

Galvanized binding wire is a type of wire that has undergone a galvanization process, which involves coating it with a protective layer of zinc. This process enhances the wire's durability, making it resistant to corrosion and rust. As a result, galvanized binding wire has become a popular material for use in various industries, including construction and manufacturing.

In the construction industry, galvanized binding wire is commonly used to reinforce concrete structures. This is because it provides a strong and durable bond between the steel bars and the concrete. The wire is also used in the construction of fences and other structures, as it can withstand harsh weather conditions and exposure to moisture without corroding.

In the manufacturing industry, galvanized binding wire is used in the production of various products such as wire mesh, barbed wire, and nails. The wire's strength and durability make it an ideal material for these applications. It is also used in the production of household items such as hangers and baskets.

One of the advantages of galvanized binding wire is its low cost. Compared to other types of binding wire, galvanized binding wire is relatively inexpensive, making it an ideal choice for use in large-scale construction and manufacturing projects.

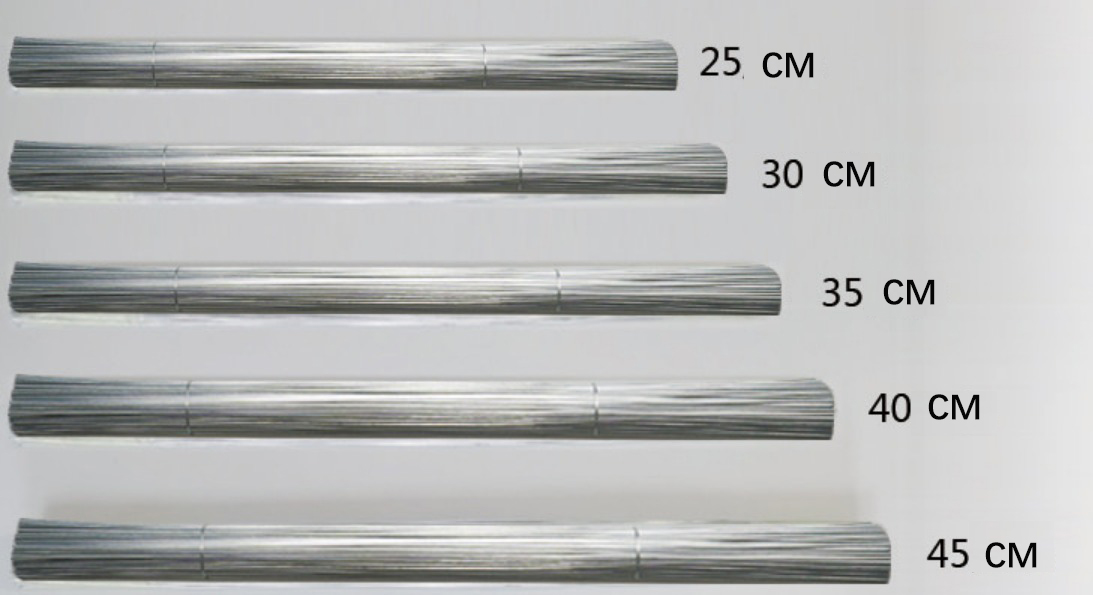

Another benefit of using galvanized binding wire is its ease of use. The wire is easy to bend and shape, allowing it to be used in a variety of applications. It can also be easily cut to size, making it ideal for projects that require custom lengths of wire.

In addition to its durability and ease of use, galvanized binding wire is also environmentally friendly. The zinc coating on the wire provides a protective layer that extends the life of the wire, reducing the need for frequent replacements. This results in less waste and a smaller environmental footprint.

When selecting galvanized binding wire, it is important to consider the wire's thickness and diameter. Thicker wires are stronger and more durable, making them suitable for heavy-duty applications. However, thicker wires may also be more difficult to bend and shape. The diameter of the wire is also important, as it determines the wire's strength and ability to withstand stress.

In conclusion, galvanized binding wire is an essential material for construction and manufacturing. Its strength, durability, and low cost make it a popular choice for a variety of applications. Whether you are reinforcing a concrete structure or producing wire mesh, galvanized binding wire is a reliable and cost-effective material that will get the job done.